The Medium and Long-Term Plan for the Development of the Hydrogen Energy Industry (2021-2035) has defined the strategic positioning of the hydrogen energy industry and its green, low-carbon development direction. The "14th Five-Year Plan" for Scientific and Technological Innovation in the Energy Sector proposes integrating renewable energy power generation with electrolytic hydrogen production and fuel cells to build a zero-carbon energy system. This approach not only enables green hydrogen production but also addresses renewable energy consumption issues, representing a highly promising development direction. Recently, the National Energy Administration issued the Guiding Opinions on Energy Work for 2023, proposing to accelerate breakthroughs in green hydrogen production, storage, and utilization technologies, and to promote the large-scale application of hydrogen energy. Since entering 2023, the industrialization process of hydrogen energy has accelerated both domestically and internationally, and green hydrogen has entered a period of rapid development.

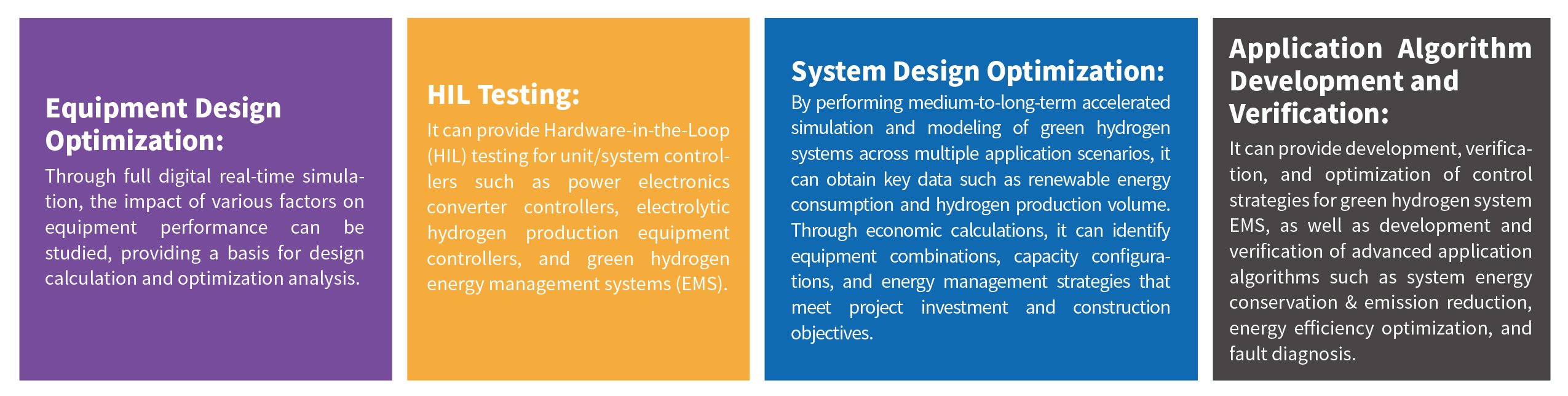

To accelerate the research on key technologies and industrial application of green hydrogen systems, the KeLiang Green Hydrogen Real-time Simulation and Testing System has been developed. The system possesses simulation and testing capabilities for grid-connected or off-grid renewable energy electrolytic water hydrogen production systems with multi-energy flows and multi-time scales, providing an integrated solution for green hydrogen system research.

n Development Management Subsystem: Green Hydrogen System Simulation Model Library iEnergyModel-H2 and Green Hydrogen System Digital Twin Software iEnergyLab

n Real-time Simulation Subsystem: Real-time simulator, I/O, and communication interface modules

n Physical Device Subsystem: Green Hydrogen System Unit Controller, Green Hydrogen System Energy Manager, Four-quadrant Power Amplifier, Green Hydrogen Physical Dynamic Simulation System

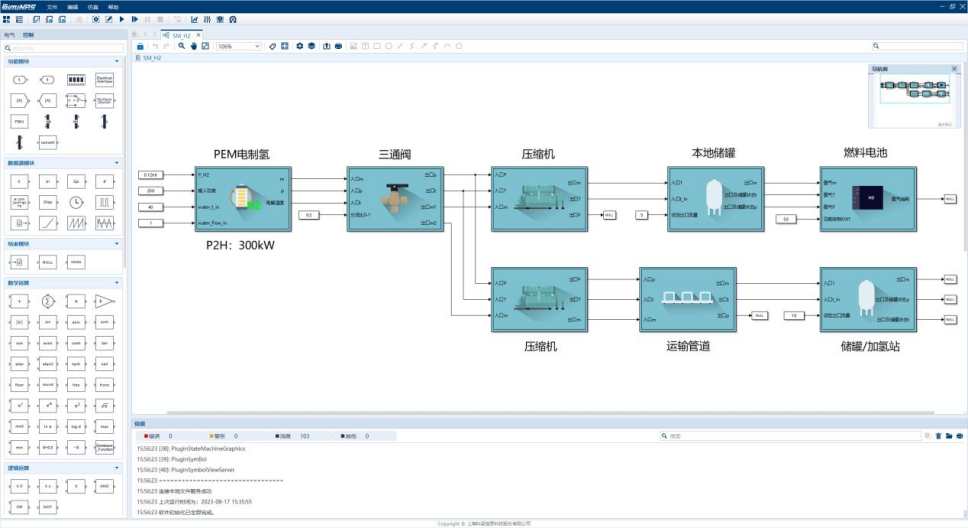

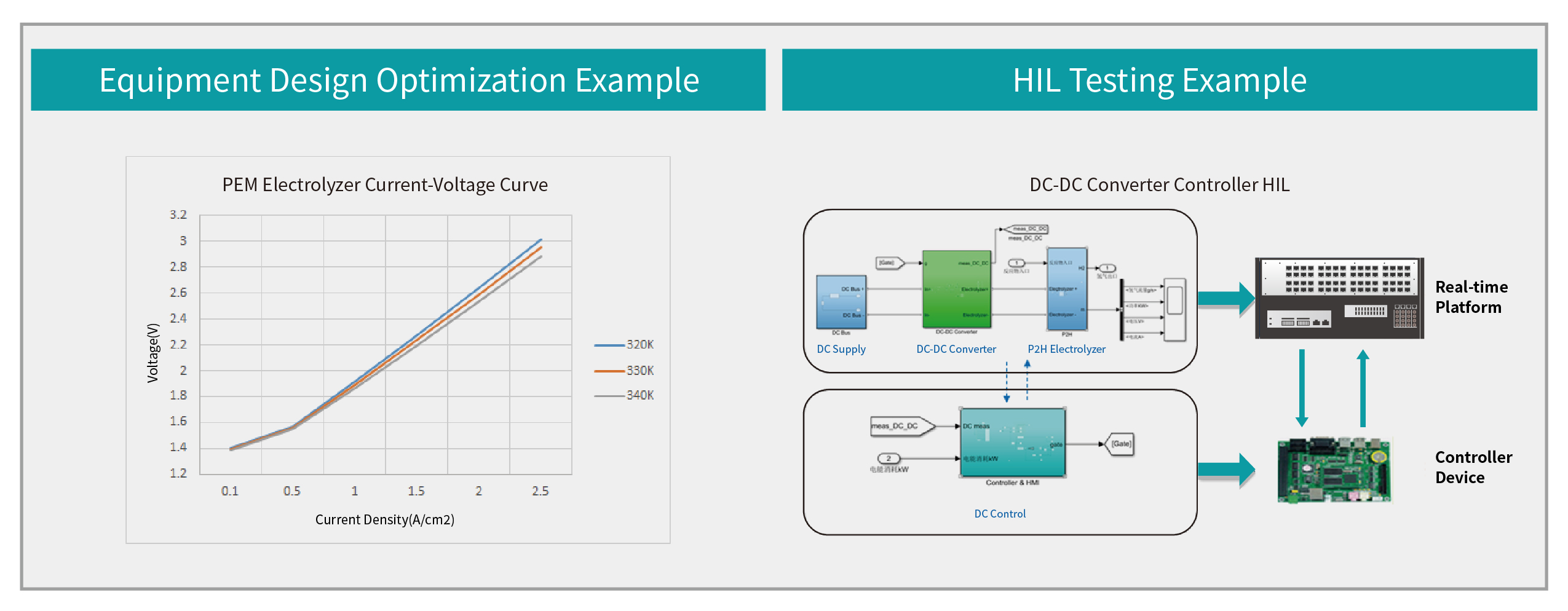

n The iEnergyModel-H2 Green Hydrogen System Simulation Model Library is developed based on the mainstream simulation software Matlab/Simulink and SimuNPS - KeLiang's autonomous and controllable, full electromagnetic transient modeling and simulation software. It contains detailed models and average models, covering equipment models across the entire industrial chain, including new energy power generation, hydrogen generation by water electrolysis, hydrogen storage, hydrogen transportation, and hydrogen application. This library enables rapid dynamic simulations at device-level, unit-level, and system-level, meeting simulation requirements for varying granularities and diverse application scenarios.

n It supports modeling of grid-connected and off-grid renewable energy electrolytic hydrogen production systems, enables multi-step simulation, achieves minute-level thermal system, microsecond-level power system, and nanosecond-level power electronics simulation applications, and provides comprehensive multi-energy coupling solutions.

n The system supports multiple relational databases and provides comprehensive capabilities for data recording, storage, retrieval, and interface functionality.

n It supports access from both simulated models and physical systems, features virtual-physical interaction capabilities, and can achieve virtual-to-physical control.

Case 1:

A typical PV-Green Hydrogen System includes models of photovoltaic power generation, electrolyzers, hydrogen storage tanks, fuel cell power generation systems, pumps, and gas pipeline networks. Based on an intelligent control strategy, the system configures rated or structural parameters for each device, with inputs including solar irradiance, temperature, and load-side demand curves:

① When photovoltaic power generation exceeds the load-side demand, the electrolytic hydrogen production is activated, converting electrical energy into hydrogen, which is then stored in local hydrogen storage tanks or transported via pipelines;

② When photovoltaic power generation fluctuates, to prioritize load-side electricity supply, the hydrogen production system automatically shuts down;

③ If load demand continues to increase while PV output further decreases, the fuel cell system activates to meet the demand, utilizing waste heat for thermal energy supply to achieve combined heat and power (CHP), satisfying diverse user energy needs;

④ By monitoring constraints including current hydrogen storage levels, grid fluctuations, regulation ranges, and carbon emissions, the operational commands for physical devices are ultimately computed.

Case 2:

A typical green hydrogen system, simulating the entire process of "photovoltaic/wind power - load consumption - surplus electricity for hydrogen production/electrochemical energy storage - high-pressure hydrogen storage - hydrogen transportation - fuel cell power supply, etc.". It includes equipment such as wind turbines, photovoltaics, electrical energy storage, electrolytic hydrogen production, hydrogen storage, fuel cells, and gas pipelines, with system operation controlled via an EMS.

① It adopts a hierarchical control strategy: When the system has surplus electricity, the Level 1 response initiates electrolytic hydrogen production, enabling energy transfer from renewable sources to green hydrogen and increasing hydrogen storage reserves; the Level 2 response activates the energy storage system for electricity storage.

② When new energy generation is insufficient, the Level 1 response activates the energy storage system for power supply; the Level 2 response initiates fuel cell power generation, resulting in a decrease in hydrogen reserves within the storage tanks.

③ The Energy Management System (EMS) integrates real-time data on renewable energy generation, power load, hydrogen storage levels, and ESS State of Charge (SOC), then issues operational commands to control the operating states of connected equipment.