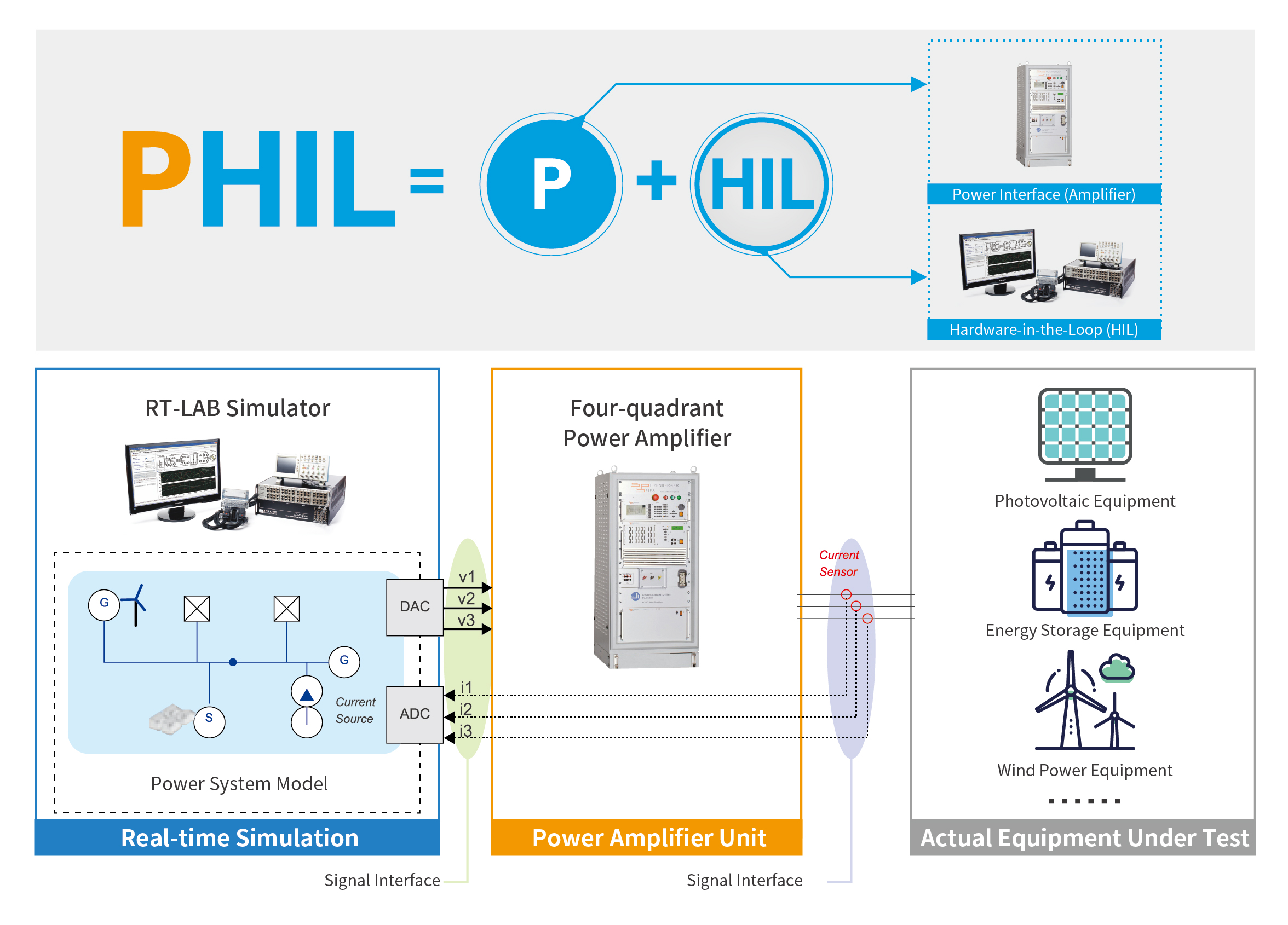

Power Hardware-in-the-Loop (PHIL) testing is an extension of traditional Hardware-in-the-Loop testing to power-level device testing. By incorporating suitable power amplification equipment and interface algorithms, PHIL testing enables not only signal-level interaction between real-time digital simulation devices and the actual Unit Under Test (UUT) but also facilitates real power exchange between devices. Consequently, it extends signal-level real-time simulation to power-level simulation, allowing the testing of actual power equipment such as energy storage devices, photovoltaic (PV) equipment, wind turbines, generators, motors, and networks composed of such devices. Currently, PHIL has been widely researched and applied, serving as a key technical means for studying distributed energy, device testing, and grid-connection technologies.

■ Wind Power Generation System Simulation & Testing

■ Electric Motor Emulation System Simulation & Testing

■ Microgrid System Simulation & Testing

■ Flexible HVDC Transmission System Simulation & Testing

■ Grid-Connected Energy Storage System Simulation & Testing

■ Aviation Power Supply Simulation & Testing

■ Grid-Connected Photovoltaic System Simulation & Testing

■ Ship Power Grid Simulation & Testing

Due to considerations of safety, reliability, and stability, the construction of PHIL systems differs from traditional HIL systems, requiring both theoretical guidance and standardized on-site implementation. KeLiang engineers possess profound theoretical expertise and can tailor customized PHIL solutions according to users' diverse technical requirements.

Advantages of our PHIL system solution:

■ Advanced real-time simulation system

■ Reasonable power amplification equipment

■ Correct power interface algorithm

■ Professional engineering implementation services

Real-time simulation system

The simulation component of KeLiang's PHIL system is based on the RT-LAB real-time simulation platform. For power electronics simulation applications, it models using MATLAB/Simulink/SimPowerSystems and combines multi-core distributed parallel computing technology from real-time simulators with FPGA high-speed digital signal processing technology. This system is capable of building SimPowerSystems power models into a real-time simulation environment. It adopts parallel computing techniques and a modular design, delivering high simulation accuracy, excellent scalability, and open software/hardware development interfaces. For node-intensive simulation systems like smart substations and microgrids, RT-LAB leverages the application-layer toolkits RT-EVENTs, RT-eDrive, and the real-time model solver ARTEMIS, employing the SSN solution scheme to resolve simulation decoupling issues in dense system real-time simulations.

Power Amplification Equipment

KeLiang supplies Linear Power Amplifiers from Spitzenberger & Spies (SPS). These amplifiers feature low latency and high bandwidth, and customized solutions tailored to users' specific technical requirements can be provided.

Product Features:

■ Low Harmonic Distortion—even under nonlinear load conditions

■ High Slew Rate: >52V/μs (Rise Time <5μs @230Vrms; fully compliant with IEC/EN 61000-4-11)

■ Input/Output Delay: <5μs

■ Large Signal Bandwidth (-3dB): DC–10kHz (extendable to 30kHz)

■ Small Signal Bandwidth: 50kHz

■ Long-Term Overload Capacity (1 hour)

■ Short-Term Overload Capacity (5–10 minutes)

■ Peak Load Capacity (up to 5ms)

■ Low Internal Impedance

Power Interface Algorithm

Before the PHIL test, our engineers will utilize RT-LAB to construct a pure digital simulation model encompassing the power grid, power amplifier, power interface algorithm, and the device under test. We will deduce the transfer functions of the simulation model, the power amplifier, and the HUT, and, in conjunction with the chosen power interface algorithm, complete a stability analysis of the entire system to ensure the safe and stable operation of the user's PHIL system.

Engineering Implementation Services

The construction and testing of PHIL systems represent a complex and emerging technology, requiring the project contractor to possess expertise in real-time simulation systems, power amplification systems, and model development. KeLiang boasts a dedicated team of PHIL engineers who provide tailored PHIL services based on the specific conditions at the customer's site.

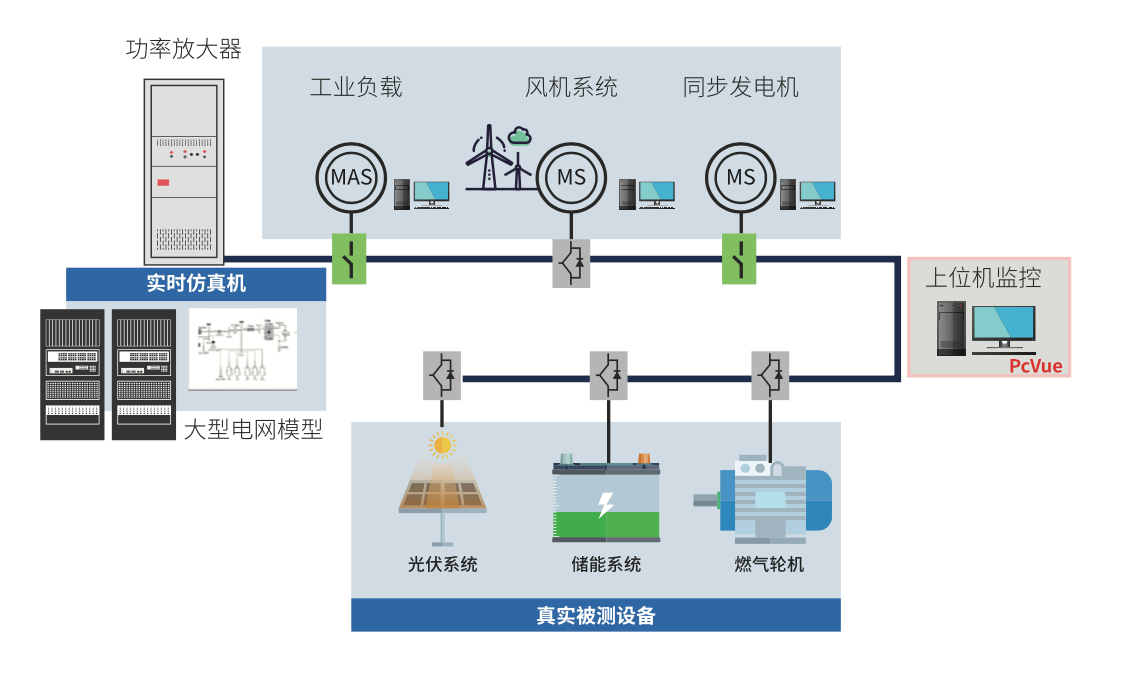

Microgrid PHIL simulation

KeLiang's PHIL solution has successfully constructed a microgrid power hardware-in-the-loop (PHIL) simulation system. In this system, KeLiang utilized RT-LAB real-time simulation equipment to achieve full digital simulation of distributed generation and energy storage devices, including wind power, photovoltaics, micro gas turbines, batteries, large capacitors, and flywheel energy storage. Prior to obtaining accurate mathematical models, physical devices were integrated into the "virtual grid" via power amplifiers to study the impacts of integrating new energy sources into the grid, such as electromagnetic transients and fault conditions. This approach facilitates the acquisition of highly accurate mathematical models for research and serves to validate these models.

PHIL Testing for PV Inverters

KeLiang's PHIL solution establishes a comprehensive test system for PV inverters, leveraging its PVS-series PV simulators to real-time simulate the operational characteristics of solar panels under dynamic climatic and operational conditions (e.g., weather changes, shading) with sufficiently rapid dynamic response. The PV inverter under test integrates the simulated power output into a grid simulator, while RT-LAB performs simulation of power systems or microgrids and controls PAS-series power amplifiers to emulate real-grid behaviors, including absorbing the inverter's converted power. This configuration completes a closed-loop PHIL test environment. The solution is scalable to PHIL testing for other new energy equipment. The following figure shows a photovoltaic testing system with a total power of 350KW established by an electric power research institute.