China's green hydrogen industry has accelerated its development since the introduction of the Medium and Long-Term Plan for Hydrogen Industry Development (2021–2035) in 2022. A wave of green hydrogen demonstration projects commenced construction in 2024, propelling the hydrogen sector into a boom period. While domestic green hydrogen initiatives are burgeoning, the industry remains in its nascent stage, grappling with widespread challenges such as economic viability, efficiency, safety, and reliability.

Currently, green hydrogen applications in China remain predominantly concentrated in chemical sectors such as ammonia and methanol synthesis. Research indicates that ongoing green hydrogen projects primarily focus on large-scale hydrogen production at new energy bases and its comprehensive utilization. However, the critical challenges for their widespread deployment and the full realization of electricity-hydrogen synergy lie in: Enhancing coordinated planning, integrated design, flexible control, and energy management capabilities across electricity-green hydrogen-chemical industrial systems.

KeLiang iEnergyLab-H₂ Green Hydrogen System Planning and Design Optimization Software addresses the engineering requirements of large-scale renewable energy-based hydrogen production systems. It provides comprehensive process simulation and analysis capabilities for electricity-green hydrogen-chemical industrial coupled systems. This enables verification and optimization of green hydrogen system planning/design schemes, while delivering technical and platform support for coordinated control and cost-effective operations of integrated electricity-hydrogen-chemical systems.

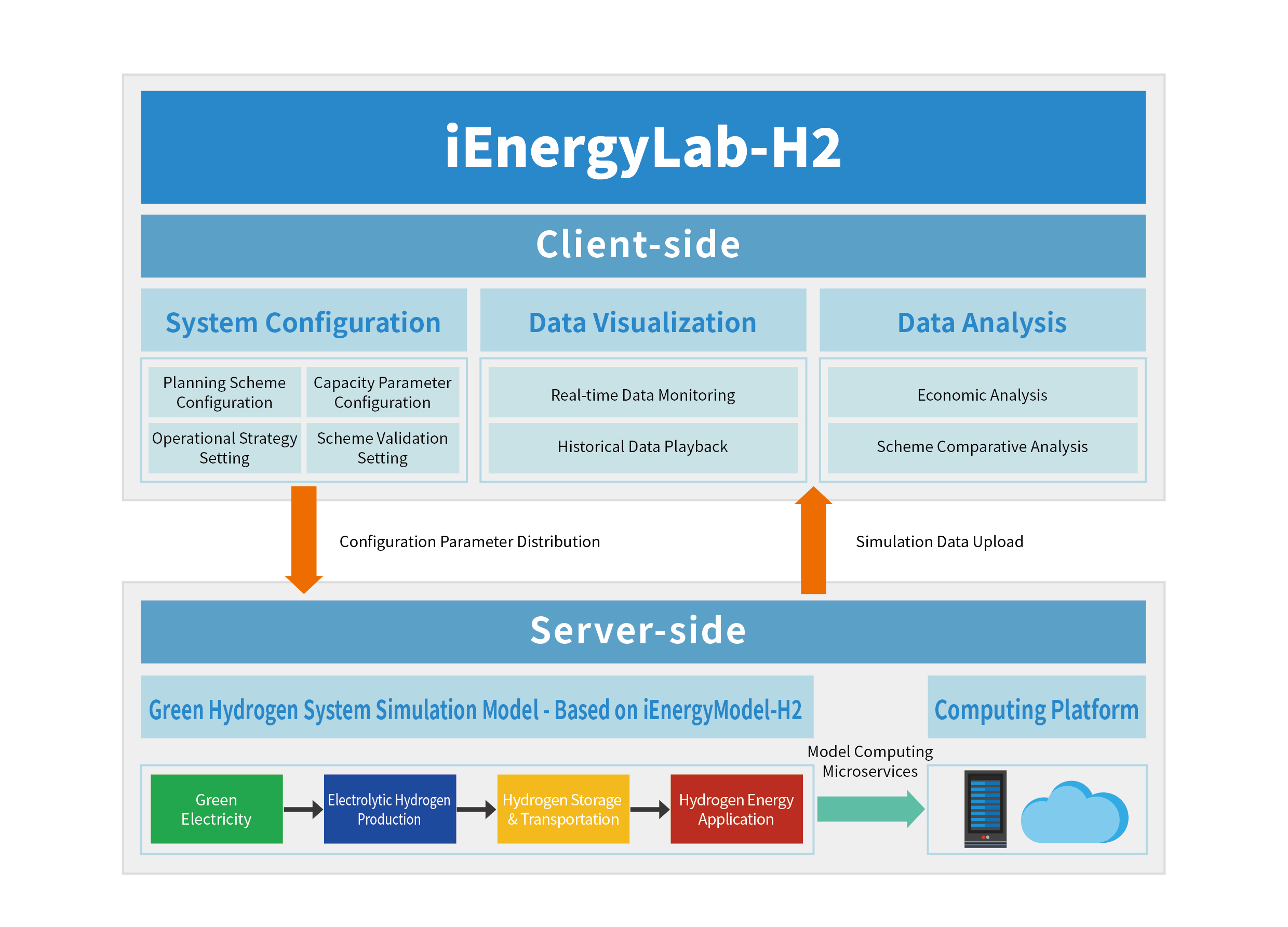

The iEnergyLab-H2 software platform comprises two core components: the Client-side and the Server-side.

Client-side: The Client-side delivers a unified graphical user interface facilitating interaction between the server and end-users, incorporating functional modules for green hydrogen system scheme design, parameter configuration, operational strategy selection, data visualization, and simulation results analysis.

Server-side: The Server-side delivers system-wide simulation computing for green hydrogen systems, encompassing a simulation model library and a computational platform. It receives user-configured parameters and computing tasks, then assigns and executes tasks across computing units via resource scheduling and model computing microservices.

n Full-Process Simulation of Green Hydrogen Systems

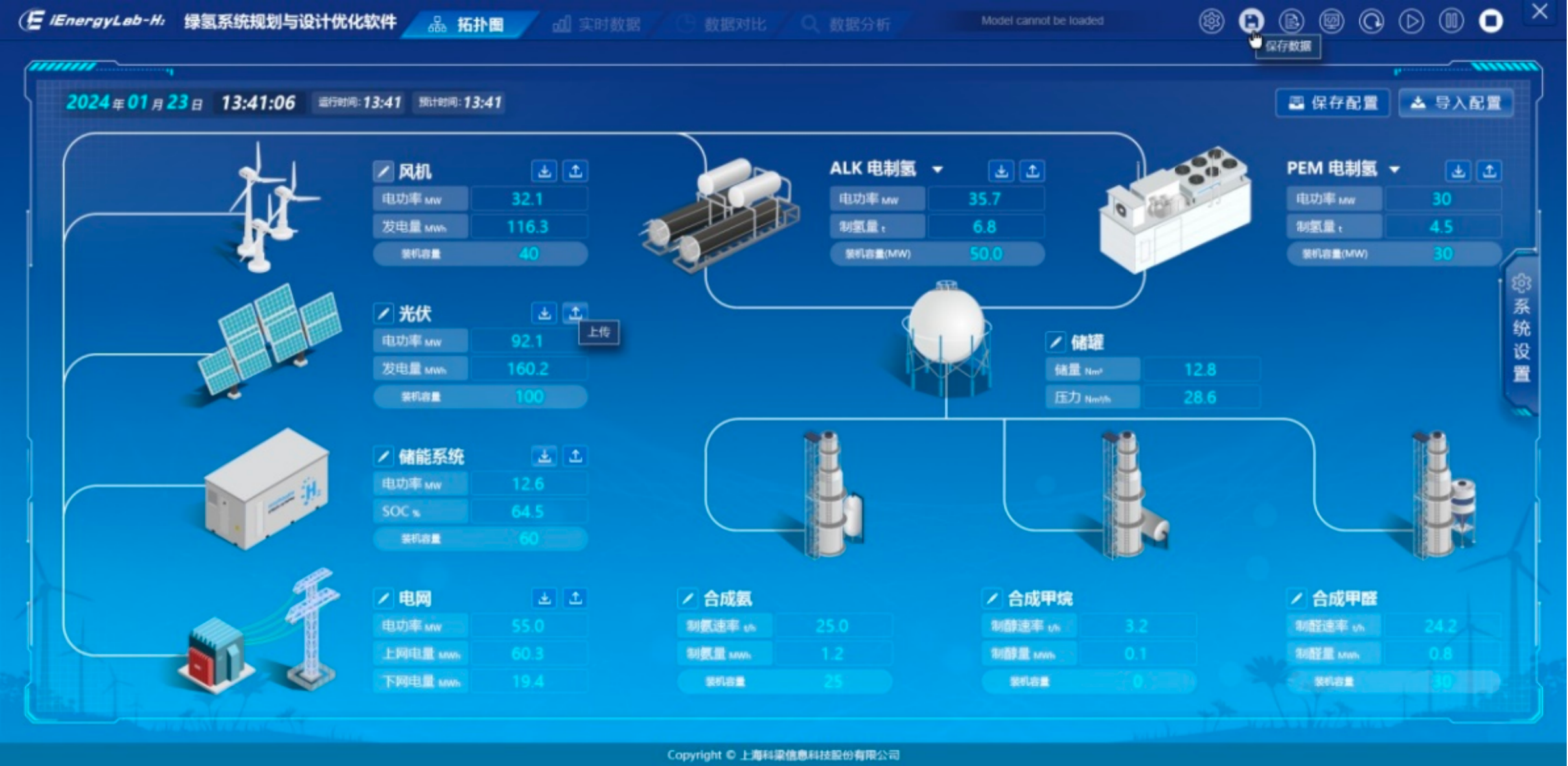

The platform integrates power supply, grid systems, energy storage, hydrogen production, and hydrogen application based on the process characteristics and control requirements of green electricity, green hydrogen, and hydrogen application scenarios (primarily chemical synthesis). This enables holistic planning and design across the green hydrogen industry chain while covering full-process simulation of hydrogen production-storage-application. It further optimizes collaborative planning and design schemes through simulation-based verification and optimization.

n Multi-scenario Simulation of Green Hydrogen Systems

Users customize green hydrogen system configurations based on energy types, power output characteristics, and chemical product demands, enabling technology selection and capacity sizing for power supply, energy storage, hydrogen production, hydrogen storage, and chemical synthesis units to explore diverse grid-connected and off-grid system configuration schemes across multiple combinations.

n Multi-Operational Mode Simulation of Green Hydrogen Systems

It provides flexible regulation strategies for different electrolyzer clusters and combined options for overall system energy management strategies to verify the overall efficiency and economics of the system under various capacity ratios and operational regulation strategies.

n Simulation of Green Hydrogen System Participation in Grid Peak Shaving: Verify the feasibility of integrating hydrogen production from electricity and chemical synthesis as highly adjustable loads, tracking new energy output, and supporting flexible operation of the large power grid.

n Data Visualization functionality

It implements real-time online monitoring of key parameters such as new energy power generation, electricity procurement, hydrogen production, and hydrogen production efficiency. Additionally, it provides a comparative analysis function for key parameters across different design solutions.

n Economic Analysis Function

Based on simulation data from key equipment operations such as renewable energy utilization hours, energy storage, hydrogen production systems, and chemical synthesis systems, it can calculate the levelized cost of green hydrogen production and green chemical products under various application scenarios, aiming to find the optimal solution that meets the project design objectives.

n Broad Applicability and Comprehensive Coverage

It supports the planning, design, and operational optimization of green hydrogen projects across diverse power source combinations, hydrogen production configurations, and end-use application scenarios. It provides technical underpinning for the cost-effective and efficient operation of such projects.

n High Model Reliability

Developed based on the iEnergyModel-H2 Green Hydrogen Simulation Model Library, this model encompasses dynamic equipment models for the entire industrial chain, including new energy power generation, electrolytic hydrogen production, hydrogen storage, hydrogen transportation, and hydrogen application. The library is constructed under a unified modeling framework tailored to multi-energy (e.g., power–green hydrogen–chemicals) and multi-timescale coupling characteristics, and has been validated through engineering applications.

n High Computational Efficiency

The green hydrogen system simulation model balances precision with computing speed, supporting accelerated simulation calculations with an acceleration ratio of up to 10,000 times or higher. It enables long-time-scale timing dynamic simulation and full-process simulation of the green hydrogen system in a short period of time.

n Diverse Operational Strategies

The system supports coordinated regulation of multi-type, multi-specification electrolyzer clusters and enables flexible selection of energy management strategies, with integrated consideration of hydrogen production equipment's cold/hot standby states, start-stop timing, start-stop sequences, and power dispatch logic.

n High User Customization Capability

The system supports user-defined calculation formulas or methodologies for economic indicators such as the levelized cost of hydrogen, while also enabling customization of additional economic/energy efficiency reference metrics and system evaluation criteria with configurable computation methods.

n High Modular Integration Capability

The platform adopts a modular structural design that facilitates seamless integration and data sharing with external systems. It can also be used in conjunction with the KeLiang Green Hydrogen System Transient Simulation Platform to simulate the operating state and control methods of equipment under extreme conditions, thereby deeply optimizing the project's design scheme and operation mode.